The Rare Events Prob

(Probability-Based) G chart (or Geometric chart) is an alternative

to a standard attribute chart when the adverse event of interest is

rare and discrete opportunities between events are counted (e.g.,

number of units or days between). The use of probability-based

control limits is recommended in order to properly control the Type

I (false alarm) error rate.

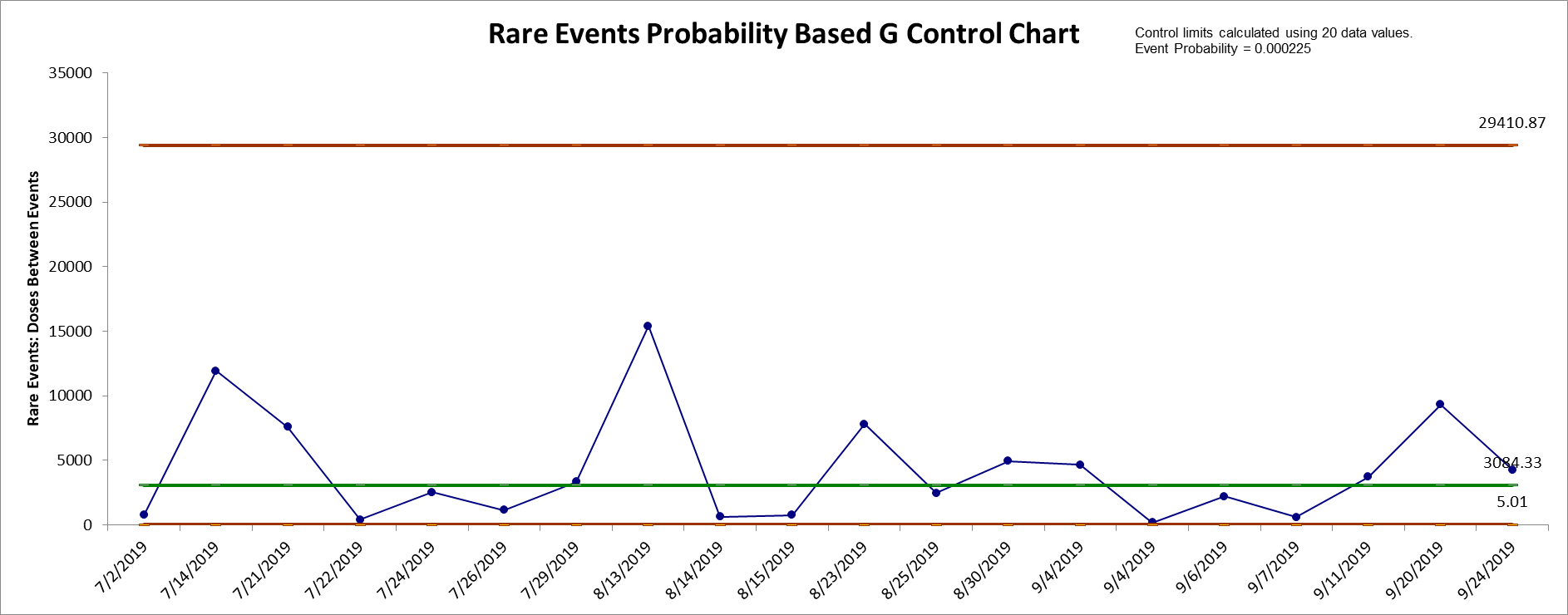

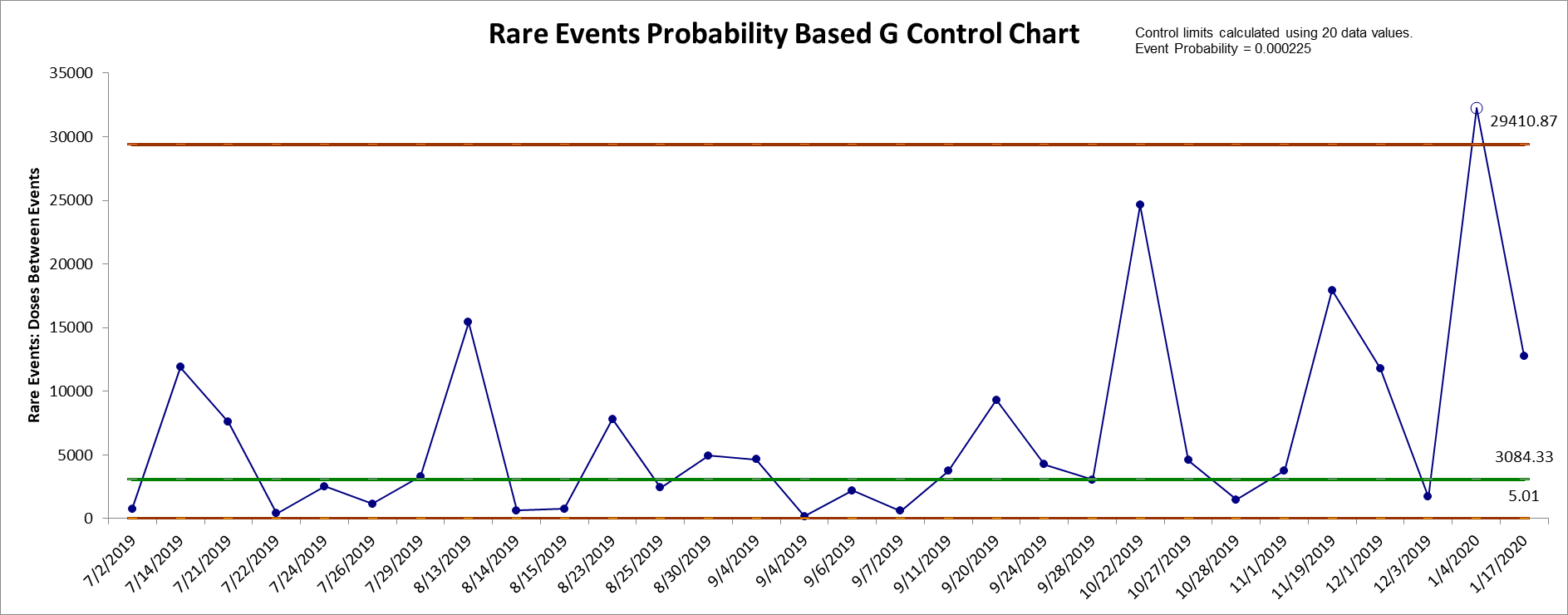

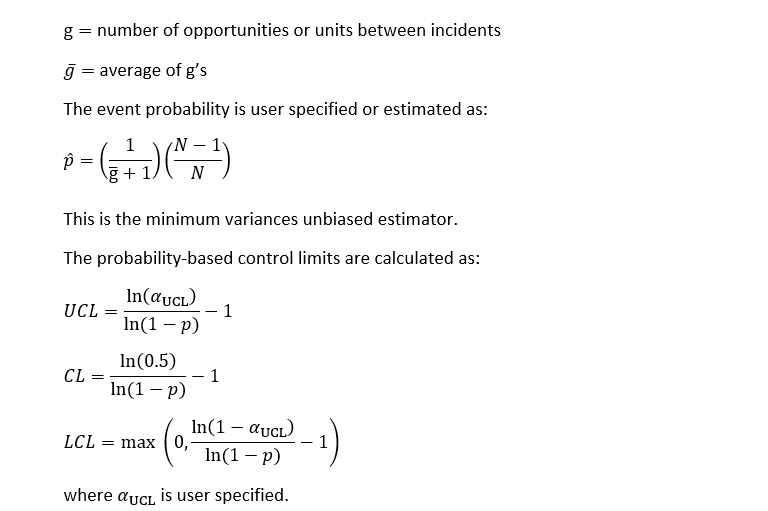

The calculation of control limits is based on the geometric

distribution. Event probability and alpha are used to compute the

non-symmetrical limits. An "out-of-control" signal above the UCL is

desirable, indicating a significant increase in units/opportunities

or days between adverse rare events. See Benneyan, 2001.

SigmaXL adjusts the Benneyan CL and LCL by subtracting 1 as done in

the UCL and does not round the limit values. Opportunities between

events are counted as 0, 1, 2, 3, … (a=0 in Benneyan Table 3).

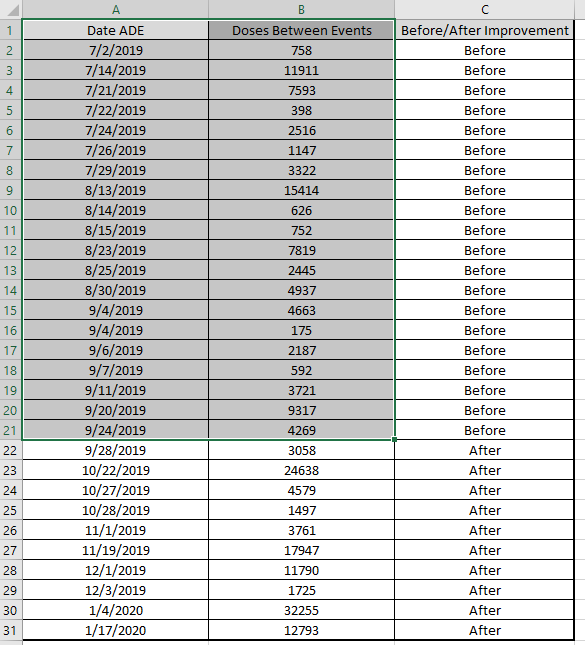

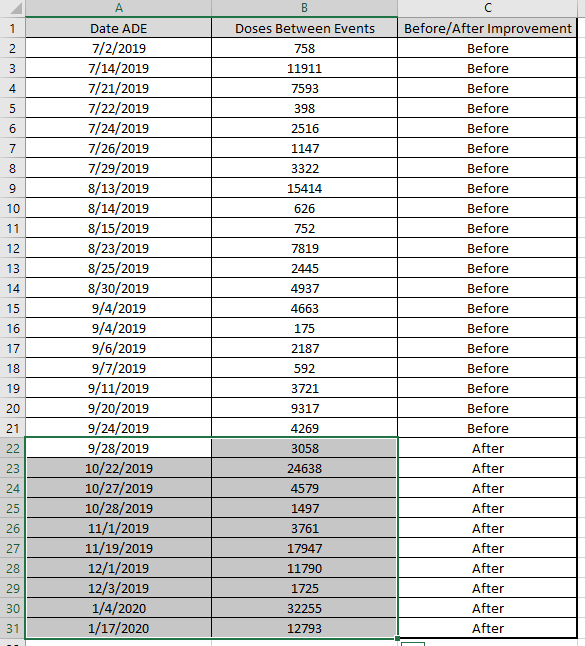

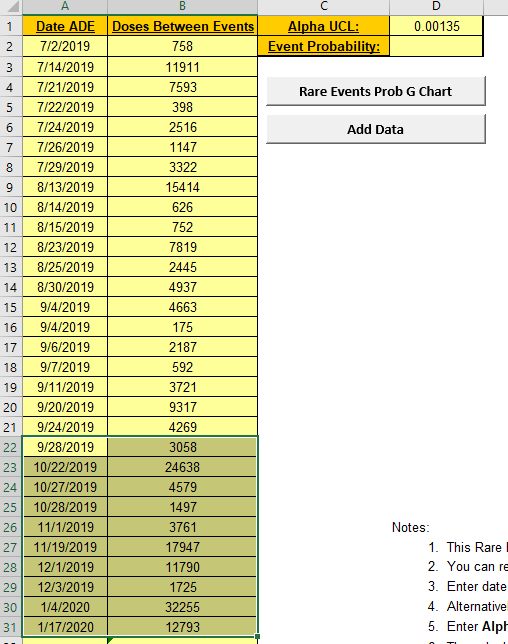

1. This Rare Events Prob (Probability-Based) G Control Chart

template should be used with days or units/opportunities between

(typically adverse) rare events.

2. You can replace the Date/Time and Days

Between column headings with any headings that you wish.

3. Enter date in the Date column. Days between are

automatically calculated and entered into Days Between

column. Cell B2 is not used in this case.

4. Alternatively, you may manually enter data in Days/Units

Between. Note, this will overwrite the cell formulas.

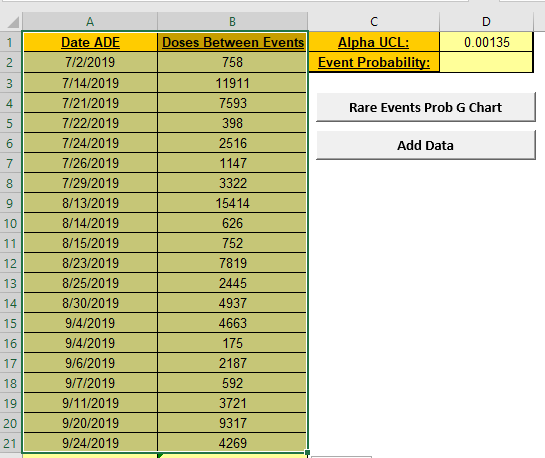

5. Enter Alpha UCL, typically 0.00135,

corresponding to the one-sided probability for UCL in a classical

Shewhart control chart with 3 sigma limits. This will also be

applied to the LCL if greater than 0.

6. The calculation of control limits is based on the geometric

distribution. Event probability and alpha are used to compute the

non-symmetrical limits. Calculated event probability is noted on the

control chart.

7. Optionally enter the historical Event Probability.

8. Click the Rare Events Prob G Chart button to

create a control chart. This will overwrite any existing control

chart.

9. After the control chart has been created and additional new

Date or Days/Units Between data

entered, click the Add Data button to add the data

to the existing chart. Control limits will be calculated using the

original chart event probability or specified event probability.

10. Add Data should only be used if there are at least 20

observations in the original chart or known historical Event

Probability has been specified.

11. An "out-of-control" signal above the UCL is desirable,

indicating a significant increase in days or units/opportunities

between adverse rare events.

12. Reference: Benneyan, J.C. (2001), "Performance of Number-Between

g-Type Statistical Control Charts for Monitoring Adverse Events",

Health Care Management Science, 4, pp. 319–336, Table 3.

Our CTO and Co-Founder, John Noguera, regularly hosts free Web Demos featuring SigmaXL and DiscoverSim

Click here to view some now!

Phone: 1.888.SigmaXL (744.6295)

Support: Support@SigmaXL.com

Sales: Sales@SigmaXL.com

Information: Information@SigmaXL.com