Case Study 4 – Catapult Variation Reduction

Introduction: Optimizing Catapult Distance Firing Process

This is an example of DiscoverSim stochastic optimization for catapult distance variation reduction, adapted from:

John O'Neill, Sigma Quality Management

This example is used with permission of the author.

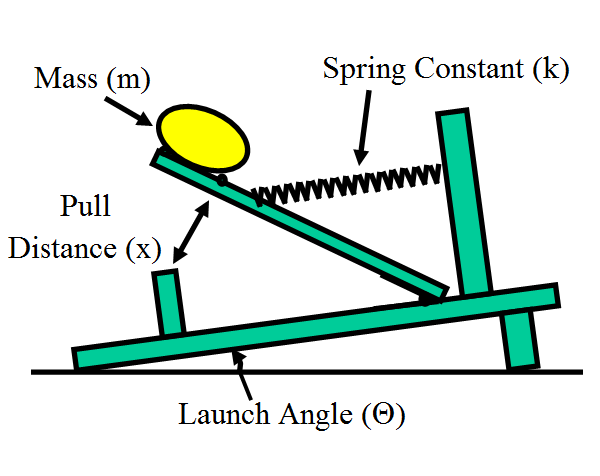

The figure below is a simplified view of the catapult:

The target catapult firing distance, Y = 50 +/- 2.5 feet.

To keep the model simple, only four factors (X’s) are included:

- Spring Constant (k) – The spring constant is the force/foot required to pull back the catapult arm (in lbf/ft.). The initial parameters for this factor: normally distributed, mean of 47.3, standard deviation of 0.1.

- Pull Distance (x) – This is the distance in feet the arm is pulled back to launch the mass. The initial parameters for this factor: normally distributed, mean of 6.0, standard deviation of 0.1.

- Mass (m) – This is the mass of the object in slugs (lbf/ft/sec^2). The initial parameters for this factor: normally distributed, mean of 0.5, standard deviation of 0.01.

- Launch Angle (θ) – This is the angle in degrees to the horizontal at which the mass leaves the catapult. The initial parameters for this factor: normally distributed, mean of 35, standard deviation of 3.

Note: The degrees must be converted into radians for input to the Excel sine and cosine functions.

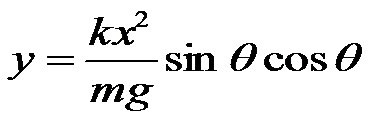

The Y = f(X) relationship is derived from conservation of energy and basic time, distance, acceleration relationships. Note that air resistance and other “real world” factors have been ignored to keep the model simple. Standard Gravity (g) is 32.174 ft/sec^2:

In this study we will use DiscoverSim to help us answer the following questions:

- What is the predicted process capability with these nominal settings?

- What are the key X variables that influence catapult firing distance Y?

- Can we adjust the nominal settings of X to reduce the transmitted variation in Y, thereby making the distance response robust to the variation in inputs?

- Can we further reduce the variation of the key input X’s in order to achieve an acceptable process capability?

|

Summary of DiscoverSim Features Demonstrated in Case Study 4: |

|

Web Demos

Our CTO and Co-Founder, John Noguera, regularly hosts free Web Demos featuring SigmaXL and DiscoverSim

Click here to view some now!

Contact Us

Phone: 1.888.SigmaXL (744.6295)

Support: Support@SigmaXL.com

Sales: Sales@SigmaXL.com

Information: Information@SigmaXL.com